|

| The Cabinet Carcasses |

Even at Home Depot, these three stock cabinets were $2500.

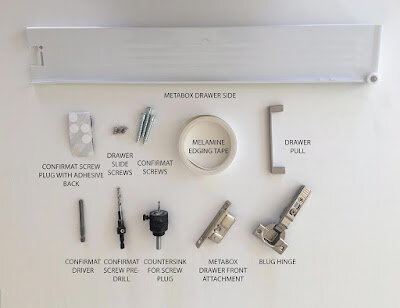

Cabinetry can be tedious work so I'm not ungrateful for that pricing. But the Shopbot in my studio was the obvious alternative. What could be done with sweat equity for a fraction of the cost? It also felt like the hardware quality could be improved on. The Blum Metabox system was used and I ordered these components, as well as some good drawer pulls at CabinetParts.com. This greatly simplify the assembly process and helped to ensure good operability. So far the project is looking like it will cost somewhere around $700 in parts.

|

| The milled panels |

It is worth noting that there is an MDF (medium density fiberboard) alternative to particleboard for the core of these products. For this application it felt unneccessary and would have sourcing the material more challenging. I still used my friendly local Home Depot for the raw Melamine sheets.

Thus far the cabinet carcasses (or boxes) are complete. I used Confirmat screws to assemble the boxes and was relieved to see I could attach the panels to each other by hand quickly and easily. The CNC toolpath writing is primarily useful for locating door and drawer hardware, which can be unforgiving with a lack of precision.

It is also important to get your cutting speed right since Melamine has a real tendency to chip. A lot has been written about how to avoid this on line. I found a compression bit really helped to minimize this although it is my single biggest concern on the project. If the drawers and doors turn out okay, the process will be posted on Instructables in the future.